Effects of radiation on composite

Radioactive materials are often thought of as fuel sources for nuclear power generation.

Radioactive materials are substances that contain radioactive nuclei, and refer to those nuclei that naturally emit particles and electromagnetic waves and change into other nuclei.

When this decay occurs, the mass decreases slightly, which is called mass defect, and it is involved in the generation of enormous energy.

This is the famous

E=mc2

derived from the theory of relativity.

The energy associated with mass defect is enormous, and 1 mg of mass defect releases the same amount of energy as 2 tons of oil.

Many people may know that the energy of atomic bombs is basically supplied by a similar principle.

Since various types of radiation fall not only from nuclear power plants but also from the natural world, if composite (FRP) is used in a structure, I think it is important to have an overview of the effects of radiation.

In this article, I would like to consider what changes occur in composite due to radiation, while looking back at past research examples.

What is radiation?

Image above was dwan by AI, inputting order that exists of electrons around atomic core

I have the impression that many media and people use the word “radioactivity,” but radioactivity means the property, or ability, of emitting radiation.

Therefore, it is appropriate to consider the impact on composite based on radiation, not radioactivity.

It is known that there are multiple types of radiation.

This is outside my specialty, but I would like to introduce it while quoting what I have researched.

Radiation can be broadly divided into electromagnetic waves and particle beams

The first thing to understand is that radiation can be broadly divided into electromagnetic waves and particle beams.

Electromagnetic waves are easy to understand if you understand them in terms of wavelength.

Electromagnetic waves are generally high-energy light with a wavelength of less than 1 nm, such as X-rays and gamma rays.

The former are electromagnetic waves generated outside the atomic nucleus, and the latter are electromagnetic waves generated inside the atomic nucleus, and are used for X-rays, CT scans, PET scans, radiation therapy, etc., respectively.

Considering that visible light is about 400 to 800 nm, the world of light that humans can see seems very narrow.

Particle beams include alpha rays, which refer to the emission of He nuclei, as well as beta rays, electron beams, neutron beams, proton beams, and heavy particle beams.

Of these, except for alpha and beta rays, they are mainly composed of electrons and neutrons accelerated by accelerators, or protons and other atomic nuclei.

When I was still a student, I remember hearing from my professor in the laboratory I belonged to that neutron rays are dangerous because they have a strong power to destroy human tissue.

In the evaluation example of the effects of radiation on composite described below, I would like to introduce one that looks at the effects of electron beams and gamma rays.

Units of radiation exposure

Let me touch on the units used to describe the amount of radiation exposure.

In the references I have used, “Gy (gray)” is often used.

Since it can be replaced with J/kg, you can understand it as energy per unit weight.

“Sv (sievert)” is used for human exposure to a radiation environment, which may be more common.

However, this is a value that indicates how much radiation was received by which part of the human body and in which area, and is multiplied by factors such as organ tissue, radiation weighting factor, and absorbed dose.

Example of evaluation of the effects of electron beam irradiation on composite

As an example of evaluation of the effects of electron beams on FRP, I would like to provide an overview using the following.

*Easy-to-process, radiation-resistant fiber-reinforced plastic

Irradiated electron beam

Using an electron accelerator (Dynamitron IEA-3000-25-2), a maximum of 100 to 150 MGy (megagray) of electron beam was irradiated using the static irradiation method.

The material was continuously cooled to prevent heating.

The irradiation environment was in the air.

IRRADIATED Composite / FRP

The reinforcing fibers are carbon fiber, glass fiber, and aramid fiber, and the matrix resin is either bisphenol A or F type epoxy, novolac type epoxy, solvent-free varnish, or BT resin (bismaleimide triazine resin).

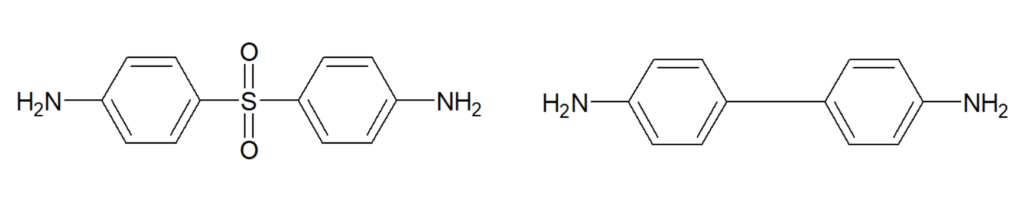

The curing agent is also changed, and the epoxy is divided into two types: diaminodiphenylsulfone, a representative aromatic amine, DDS, and diaminodiphenylmethane (DDM).

The structural formulas of DDS and DDM are as follows (left: DDS, right: DDM).

Dawn by FRP Consultant

The fiber part number is not written, but the glass fiber is E-glass, and the base material structure is either UD (unidirectional material), plain weave, or satin weave regardless of the fiber.

Composite property change evaluation method

In addition to material tests such as compression properties (strength, elastic modulus), tensile strength, bending properties (strength, elastic modulus), and interlaminar shear strength (short beam), fracture surface observation is performed using SEM.

Summary of results

Material properties

Regardless of the material composition of the FRP, if the irradiation is around 60MGy, for example, no significant change is observed in the flexural modulus.

The only combination where the modulus decreases from this irradiation dose is the combination of Bis-A type epoxy + carbon fiber.

We believe this is what has led to the conclusion that Bis-A type epoxy does not have high electron beam resistance.

On the other hand, when looking at strength, it seems that the interlaminar shear strength decreases overall depending on the amount of electron beam irradiation energy.

Most of them seem to show a tendency to decrease above about 30MGy.

On the other hand, there is also a behavior where the strength increases in the early stages of irradiation.

As for tensile strength, CF plain weave + Bis-A type epoxy (DDM) and aramid plain weave + novolac type epoxy show a decrease in response to electron beam irradiation, while the glass fiber reinforced one shows some decrease but maintains its strength overall.

Compressive strength tends to show a gradual decrease in properties according to the amount of electron beam irradiation, but the properties of CF UD + Bis-F type epoxy (DDM) remain almost unchanged even after irradiation with 150MGy of energy.

GF plain weave + Bis-A type epoxy (DDS) showed a tendency to decrease in bending strength from the early stage of irradiation, and CF plain weave + Bis-A type epoxy (DDM) showed a significant decrease in properties after irradiation with 100MGy, but no significant decrease in strength was observed.

About SEM images

SEM images of the fracture surface of the test specimens after bending tests with and without electron beam irradiation are posted.

Looking at the images before electron beam irradiation, it can be seen that resin remains on the fiber surface.

Furthermore, since the resin appears to be burred in many cases, it is inferred that the fracture mode was mainly shear (Mode II).

Although bending tests are inappropriate for evaluating the properties of FRP because they are a combination of tension and compression modes, it is possible to infer the main loading mode from the fracture cross section like this.

Regarding the fact that the resin becomes ragged in shear mode, please refer to the following literature, which contains images and explanations.

High radiation exposure breaks molecular chains in matrix resin

I would like to express my personal opinion on the SEM images seen in this study.

The SEM images show that the greater the cumulative energy of neutron irradiation, the less resin there is on the fibers.

It also states that voids, presumably due to gas generation, were seen in the final sample irradiated with a high energy dose of 150MGy.

I personally doubt whether such a phenomenon actually occurred.

However, the possibility cannot be denied that the polymer chains in the resin are broken by irradiation with high-energy electron beams, resulting in low molecular weight, which may lead to gasification (vaporization) or gelation.

In fact, there are literature that look at radiation degradation of matrix resins in terms of the degree of gelation, and this is an interesting approach.

※References

Effect of fibers on radiation degradation of fiber-reinforced plastics (Japanese only)

In the early stages of radiation exposure, FRP strength and rigidity can improve

This is a result that has been stated in other literature.

Not limited to electron beams, material properties can improve in the early stages of radiation exposure.

This is not so strange from the perspective of polymers, and we speculate that radiation probably generates radicals in part of the molecular chain, which then bond with other functional groups, causing a reaction similar to radical polymerization.

In the recommended heating process for FRP based on thermosetting matrix resins, it is common to leave a certain amount of uncured parts without aiming for 100% cure.

I think it is reasonable to assume that this uncured part was involved in the polymerization reaction caused by radiation.

Regarding the many statements that CF has higher radiation resistance when comparing CF and GF

When comparing FRPs made of multiple types of reinforcing fibers, such as CF and GF, as in this case, the results generally tend to show that CF has higher radiation resistance.

The main reason for this is often that CF has higher adhesion to the matrix resin, and I think this is true.

On the other hand, it is the matrix resin that loses properties due to radiation, so this does not necessarily apply depending on the material evaluation method or base material composition.

For example, in the results of this case, the compressive strength of CFRP is reduced according to the amount of irradiation energy.

Therefore, I think it is dangerous to assume that CFRP is safe against radiation.

Radiation resistance also changes depending on the type of matrix resin and hardener

This is probably the most interesting part of the results of this case.

Novolac type epoxy > Bis-F type epoxy > Bis-A type epoxy

The order of decreasing radiation resistance is shown.

In terms of hardeners, DDM tends to suppress the embrittlement of resins caused by electron beam irradiation, although slightly, compared to DDS.

I feel that the selection of matrix resin is important.

Example of evaluation of the impact of gamma ray irradiation on composite

Finally, I would like to introduce another evaluation of the impact resistance of FRP irradiated with gamma rays.

The reference is as follows.

Irradiated gamma rays

Using equipment from a cobalt-60 gamma ray irradiation facility, irradiation was performed at 1kGy/h for up to 500 hours.

The cumulative irradiation dose was 0.5MGy.

The irradiation was performed under two conditions: under vacuum and in air.

The information referenced this time seems to be the results only for FRP irradiated under vacuum.

Radiation-irradiated FRP

The reinforcing fiber is carbon fiber (M60JB or T300), the matrix resin is epoxy resin 3900-2 for both, and the lamination structure is [45/45/0/0/-45/-45/90/90]s for M60JB and [45/0/45/0]s for T300.

Method of evaluating FRP characteristics changes

We visually observed whether there was a difference due to the presence or absence of gamma ray irradiation.

Then, we used a two-stage gas gun to collide and penetrate the FRP with a 1mm diameter aluminum (A2017-T4) projectile at a speed of about 2.5km/s, and confirmed whether there was a correlation between the destruction form and the presence or absence of gamma ray irradiation.

Summary of results

No surface changes due to gamma ray irradiation were visible to the naked eye, but a difference in color (described as green coloring) was observed.

Looking at the state after the projectile hit, no significant difference was observed in the destruction morphology, but the image shows that the specimen irradiated with gamma rays had a larger through hole.

The article also compares the FRP fragments (scattered toward the projectile impact surface) generated by the collision of the projectile, and states that the specimens irradiated with gamma rays tended to be elongated.

Below, I will give my personal opinion on the evaluation results.

Gamma rays may have accelerated FRP deterioration

Although the results referred to this time are preliminary, it is very interesting that high-speed collisions were used as the evaluation method.

Gamma ray irradiation enlarged the through hole, and many of the fragments generated after the collision were integrated with the matrix resin and reinforcing fibers, suggesting that gamma ray irradiation may have led to a decrease in adhesion between the matrix resin and reinforcing fibers and a decrease in the properties of the matrix resin.

I think it is safe to assume that gamma ray irradiation also causes changes in FRP properties similar to those caused by electron beams as mentioned above.

I would like to mention one thing that I felt throughout the study.

FRP’s properties do not deteriorate easily due to radiation

There are not many cases where the radiation resistance of FRP has been evaluated, but looking at the numerical data,

I believe that “FRP’s properties do not deteriorate easily due to radiation.”

In many literature, the properties of FRP change at tens of MGy or more.

For example, let’s take radiation therapy, which uses relatively high radiation energy.

I referenced the numbers from the following site.

※Reference information

About radiation therapy/National Center for Global Health and Medicine Hospital (Japanese only)

According to this, it says that 2Gy of radiation is irradiated in about 1 or 2 minutes.

For example, if you try to irradiate 24 hours a day, 365 days a year at 2Gy/min, it will take 3472 days to reach 10MGy.

That’s nearly 10 years.

Actually, the changes in FRP’s properties depend on the evaluation method and material composition, but considering that it is about 30 to 50MGy, it will take about 30 to 50 years by simple calculation.

Although the effects of radiation cannot be ignored, I think it is more important to consider other environmental degradation factors, such as humidity, temperature, ultraviolet rays, ozone, and contact with acids, alkalis, and organic solvents, when considering the durability of FRP.

Summary

We have introduced the fact that various evaluations have revealed that radiation can be a factor in degrading the material properties of FRP.

However, since the effect requires enormous energy of tens of MGy or more, it may be important to take a broader perspective that considers other environmental factors as well, rather than just radiation.

In terms of material properties, it has been shown that interlaminar shear properties are the most sensitive to changes due to radiation, and it is speculated that the main cause of the deterioration of properties is the matrix resin and the adhesion between the resin and the reinforcing fibers.

In addition, it should not be forgotten that resin composition, such as the structure of the main chain of the matrix resin and the type of hardener, affects radiation resistance performance.

We hope that this will be an opportunity to recognize that radiation, including radiation that exists in nature, is one of the factors that can degrade the properties of FRP.